Easily integrate KFI applicators into your lines and boost productivity

KFI’s Print-and-Apply systems are high-performance machines designed to automatically print and apply labels on pallets, packages, and various types of packaging, as well as directly onto products and conveyor belts.

Why companies choose our automatic applicators

High-precision printing

Fully automated processes

Consistent workflows

Accurate product identification

Rapid application

Frees up resources for other priorities

Handles high volumes

Real-time data updates with your information system

Explore our comprehensive range of automatic applicators, download the full catalog

We are the main partners in Italy of the leading vendors in the industry.

Why choose the electric applicator?

The electric applicator offers several advantages over the pneumatic version, including better speed, precision, and cost savings.

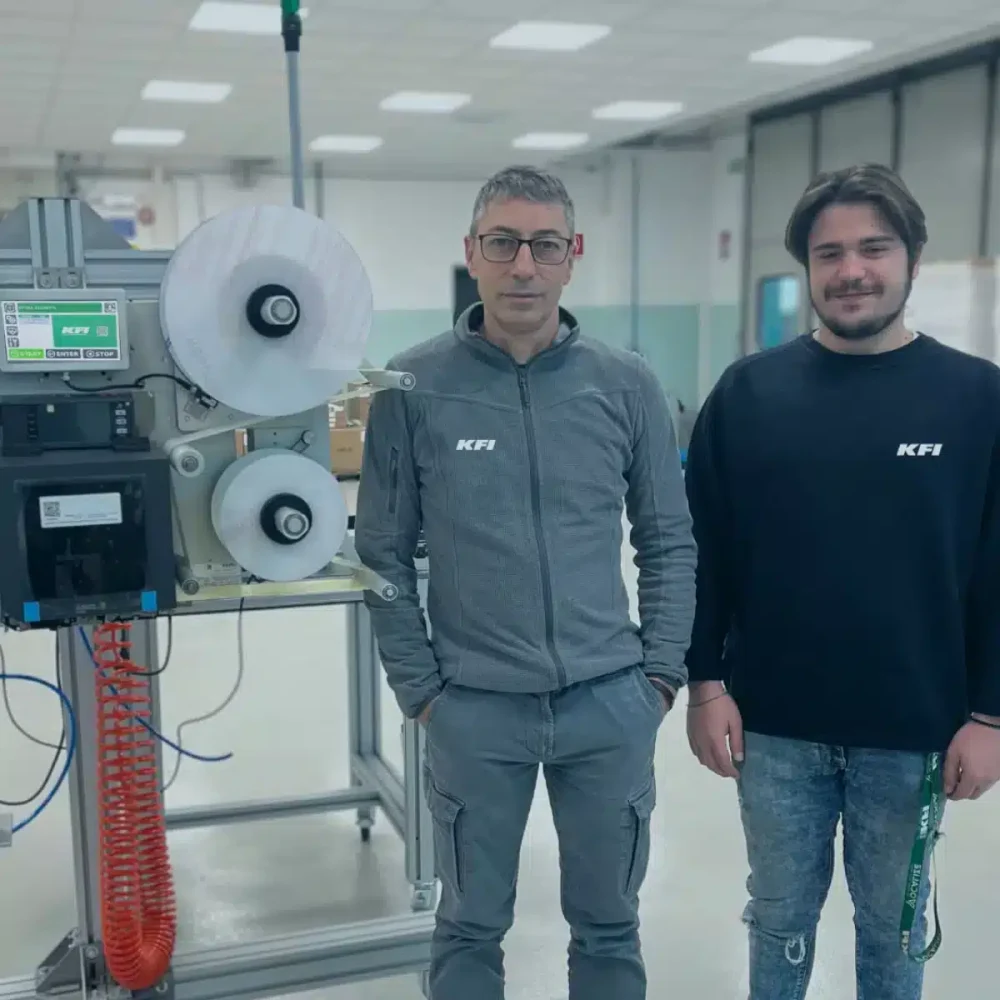

Key figures that highlight our leadership in automatic applicator implementation

300+ machines installed

On-site support within 24 hours

Team of specialized technicians

Dedicated assembly and testing area

Your trusted partner throughout the design, installation, and testing process.

Our expertise and experience enable us to follow a proven process to ensure flawless functionality while minimizing installation and production startup times. With KFI, you’re in the hands of a reliable partner that supports you at every stage, including operator training.

1. Site visit

Preliminary process analysis and feasibility study

2. Design

Identification and design of the applicator with inline integration

3. Pre-installation

Configuration and testing of all components at the KFI Automation Area

4. Installation

Integration with the information system and the automation line; anchoring, structural and functional connections; commissioning

5. Tuning and testing

Tests, print and application trials, fine tuning, and final testing