Introduction

Oniverse has adopted KFI’s software solutions to centralize label printing processes, significantly improving efficiency and global control. The integration with the Loftware platform has streamlined data synchronization between manufacturing plants and distribution centers.

Oniverse

Oniverse, formerly known as Calzedonia Group, is a leading Italian multibrand company founded in 1986. Today, it includes several well-known fashion brands: Calzedonia, Intimissimi, IUMAN – Intimissimi Uomo, Tezenis, Falconeri, Atelier Emé, and Antonio Marras. The Group is also active in the Food & Wine and Yachting industries.

The full product lifecycle—from design to in-house manufacturing to global distribution—is managed primarily within the Group. Today, the collections are sold exclusively through a network of over 5,700 mono-brand stores, both owned and franchised, in 57 countries.

Customer

Objectives

Centralize control of print layouts

Modify layouts from a single platform

Reduce dependency on specific hardware and local systems

Enable offline operations through automatic synchronization

Achieved Results

Improved management and control of printing processes

Enhanced efficiency in information flow between plants and warehouses

Fewer printing errors

Increased flexibility in managing labels for different markets and languages

THE CHALLENGE

Fragmented printing management: a global issue

Oniverse faced several operational limitations caused by a fragmented printing system. The main issue was the lack of centralized control over print layouts, which hindered consistent and accurate global label management.

Modifying label designs was complex, especially when updates needed to be applied simultaneously across multiple manufacturing and logistics sites.

The inability to synchronize data and layouts across facilities led to inefficiencies and increased the risk of errors, negatively impacting business operations.

THE SOLUTION

Oniverse transforms its labeling process with KFI and Loftware

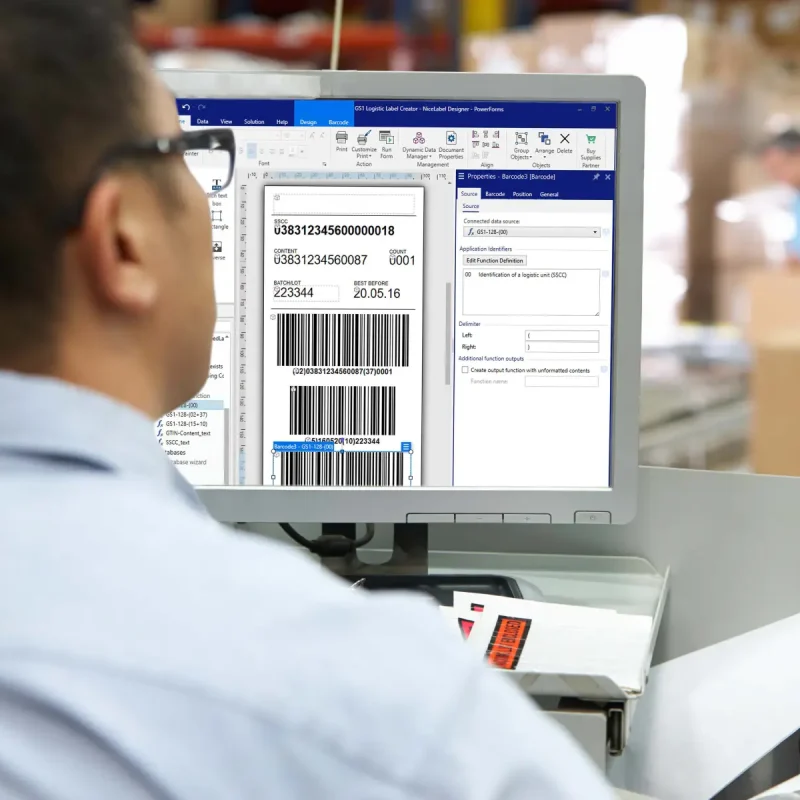

To centralize the management of label and tag printing – including care labels, price tags, and additional labels for foreign markets – Oniverse chose KFI’s Enterprise Labeling Management (ELM) software services integrated with Loftware’s label management platform.

The implemented system allows access through personalized logins with role-based permissions. Users can retrieve all necessary printing data by entering article information (SKU, color, size), which is synchronized in real time with the central database at the Verona headquarters.

Once the data is entered, the system automatically pulls in symbols, pictograms, and other key details to compose the label, optimizing the printing process.

Through Loftware integration, label layouts are managed centrally, enabling customizations for each market, including multilingual printing.

The system also operates offline in case of connectivity issues and supports an annual printing volume of over 3 million labels with minimal error margins. Additionally, the integration of high-speed printers has further improved operational efficiency by centralizing and streamlining the entire global labeling process.

KFI Enterprise Labeling Management

Thanks to ELM services, KFI optimizes the integration of labeling processes in the fashion retail industry. Its customized systems collect all data required for printing from the company’s management software into a dedicated database and integrate with Loftware for centralized label design and efficient print operations management.

THE RESULTS

Efficiency and control for global label printing

By adopting KFI’s customized ELM software services, Oniverse was able to streamline its labeling process, reduce operational costs, and enhance the quality of printed information. Integration with Loftware added significant value by delivering a centralized, highly flexible solution that meets the needs of global production and logistics. Thanks to this system, Oniverse has achieved greater efficiency and accuracy in its operations, moving toward a smarter, more digitalized process landscape.

“Thanks to the solutions provided by KFI, in partnership with Loftware, Oniverse successfully addressed its needs, significantly improving the efficiency and control of printing operations in both production plants and distribution centers. The system enables much more accurate control over print layouts and material usage.”

Marco Gobbi, Head of Purchasing & Licensing Department