We work alongside companies in the implementation of innovative projects to optimize the supply chain. Our focus is on value recovery in all the internal and inter-company operations of the supply chain.

Our strategic and operational contribution develops over four main guidelines:

Business Innovation

We work together with the company management in the formulation of innovative solutions able to offer a competitive advantage and to support new business models.

Process Optimization

We analyse the existing processes to identify the areas for improvement, to remove inefficiencies, improve performances and reduce costs.

Digital Transformation

We help companies reshape their organization and processes to reap the full benefits of the advantages offered by latest-generation digital technologies.

System Integration

We integrate the new technologies with the customer’s information systems and infrastructural environment so that goods and information flow quickly, regularly and without “frictions”.

KFI’s approach

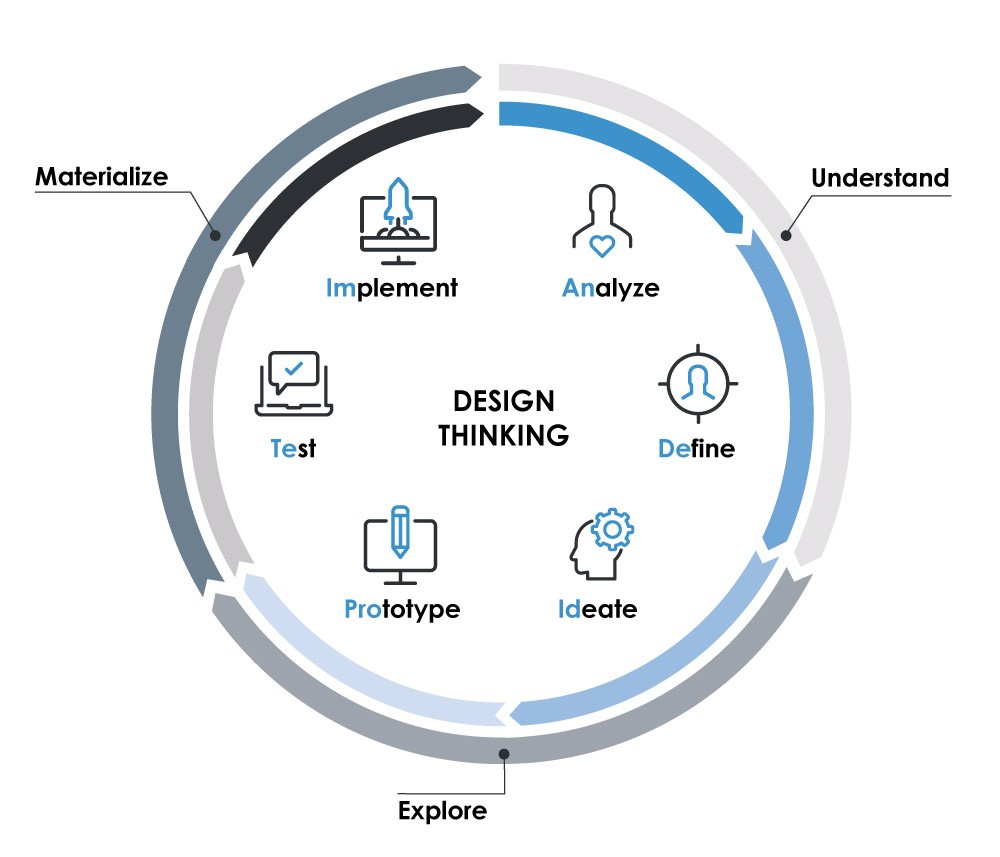

Our approach is characterized by the concreteness and pragmatism in the management of all the stages of the project. From analysis to planning, until implementation and roll-out, we work using agile and qualified methods to achieve the desired results within provided times.

The way we work draws its inspiration from the principles of Design Thinking, a company management method based on strategic design. Design Thinking involves the customer, specialists and users in a creative process which allows defining original, efficient and shared solutions more quickly and with fewer risks.

We perform consultancy activities within Logistic & Production Operations, with a particular focus on the following areas of competence:

Inbound logistics

- Logistic processes remapping

- Warehouse layout

- KPI analysis

- Tools and technologies

Production intralogistics

- Material Flow Replenishment

- Electronic Kanban

- Tracking

Reverse Logistics

- Returns selection and cataloguing

- Refurbishment activities

- KPI calculation

- Economic returns of the Reverse Logistics analysis

- Tools and technologies

Production

- Workstations computerization

- Documents management (cycles/instructions/quality control)

- Processing tracking

Outbound logistics

- Logistic processes remapping

- Multi-channel logistic (retail, B2B, B2C, e-commerce, pick&pay)

- KPI analysis

- Tools and technologies

Retail Logistics

- New distribution processes

- Logistics for Hybrid Shop

- Incoming and outgoing goods tracking

- Returns classification

- Tools and technologies